High-precision machining for demanding industrial parts

( 34) 93 383 45 31

administracion@mecanizadosdelbesos.com

Machining Division

The manufacture of industrial parts does not allow for errors.

An out-of-range tolerance, a poor finish, or a delivery delay can halt an entire production line.

That's why our precision machining is designed for companies that need absolute reliability.

We manufacture machined parts and components for sectors where quality is non-negotiable.

Pharmaceutical, chemical, biotechnological, petrochemical, cosmetic, agri-food or aeronautical.

Pieces that fit together perfectly the first time. Processes that deliver. Results that last.

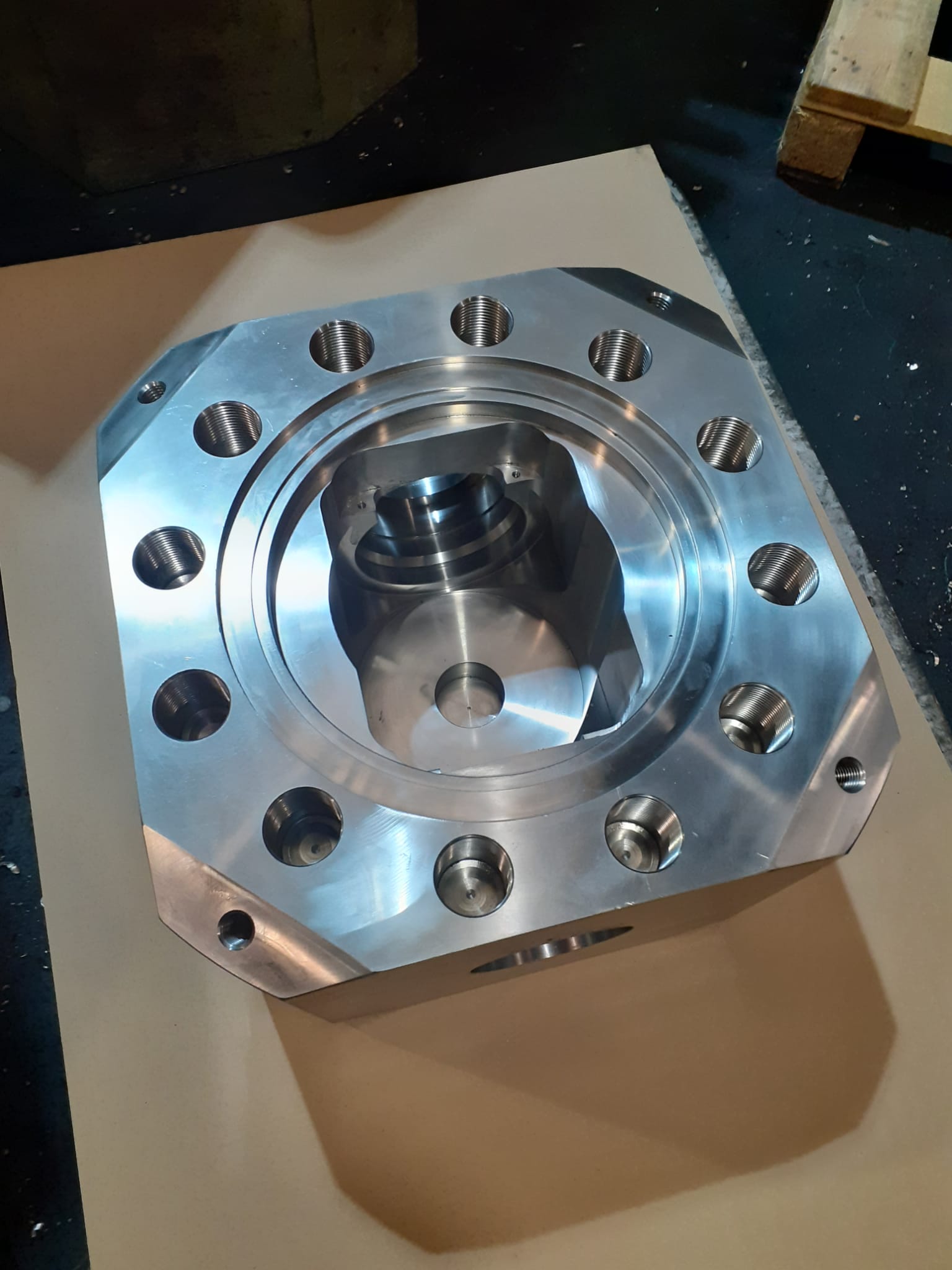

With over 50 years of experience, we combine advanced CNC machining, technical knowledge and metrological control to transform casting and forging into precise components, ready to work in the most demanding conditions.

What does our machining service include?

Our machining services go beyond simply manufacturing a part. We bring safety, precision, and continuity to your production process.

Extreme precision in every component

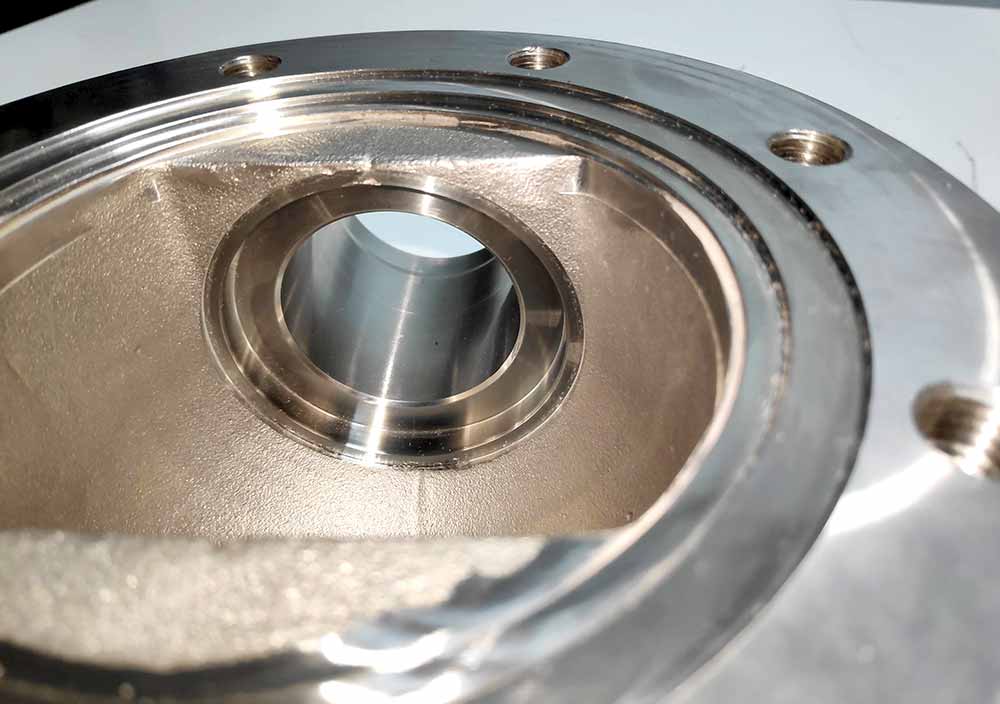

We work with tolerances as low as 0.02 mm and surface finishes with a roughness of 0.2 µm. This ensures a perfect fit, reduced wear, and a longer part lifespan.

Capacity for large and complex parts

We machine parts up to 1,000 mm in diameter, both single units and short or medium production runs. Ideal for valves, pumps, machined bodies, and structural components.

Total versatility of materials

We perform machining on a wide range of technical materials, from stainless steels to special alloys, always using the appropriate process to maintain their mechanical properties.

Comprehensive end-to-end solution

We handle the entire process. From initial engineering to final finishes and assembly.

Fewer suppliers. Fewer risks. More control.

Reliability for critical sectors

Our machining processes are designed to meet strict regulations and withstand harsh environments.

High pressure, temperature, corrosion or constant chemical contact.

High-precision CNC machining division

Our Machining Division has advanced CNC turning and CNC milling technology, supported by hand lathes and drills for specific operations.

This combination allows us to adapt each process to the piece.

We don't force standard solutions. We design the optimal machining for each component.

For over five decades, we have developed our own tooling that improves repeatability, reduces lead times, and increases accuracy.

Especially in valve machining for the petrochemical sector, where experience makes the difference.

Specialized machining services

Every project is different. Every piece has a defined technical function.

That's why our specialized machining services are tailored to the real needs of your industry.

We analyze the end use of each component, the material, and the necessary tolerances.

Only in this way can we guarantee reliable, precise parts that are ready to work from day one.

Machining of all types of parts

We manufacture custom components from cast or forged materials. From simple parts to complex geometries with high technical requirements.

Machining in special materials

We specialize in:

- Duplex and superduplex machining

- Machined from F316 stainless steel

- Machined from F316L stainless steel

- Machined from F304 stainless steel

- Machining in Inconel

- Machining of foundries

Each material requires precise parameters. Correct speeds, tools, and strategies are essential to avoid internal stresses and deformations.

High-quality finishes

We perform finishes with controlled roughness between 0 and 2 µm, ideal for components that require sealing, hygiene or low friction.

Heat treatments and pickling

We improved the mechanical properties and chemical resistance of the parts. All coordinated to avoid compromising the final tolerances.

Assemblies and couplings of assemblies

We deliver ready-to-install kits. Adjusted, checked, and assembled under technical control.

Surface copying and reverse engineering.

We reproduce existing parts without blueprints. We generate accurate CAD models using 3D scanning and reverse engineering.

Metrology and dimensional control

Each part is checked with advanced measuring equipment.

We guarantee that it meets the technical specifications exactly.

Urgent machining

We offer an urgent machining service for unforeseen shutdowns and immediate production needs.

We manufacture priority parts quickly, maintaining tolerances, finishes, and metrological control. Less downtime. Same precision.

Why choose us for your machining needs?

Proven experience

Over 50 years in the industrial machining sector. We know how to anticipate problems before they arise.

Specialization in demanding sectors

We work for industries where failure is not an option. Petrochemical, pharmaceutical, aerospace, or biotechnology.

Technology and human knowledge

High-capacity CNC machines combined with expert technicians. Technology without expertise is not enough.

Flexibility and commitment

We adapt to your deadlines, volumes, and technical needs. We respond when you need us most.

We respond with urgent machining services when time is a critical factor and production cannot be stopped.

Demonstrable quality

Controlled processes, traceability, and metrological verification. We don't promise precision. We measure it.

Request your machining quote now

If you're looking for a precision CNC machining supplier who understands the importance of every micron, you've come to the right place.

Tell us about your project. We'll analyze your piece. We'll propose the best technical and economic solution.

Request your quote or contact our technical team today.

We transform your designs into reliable, precise, and performance-ready parts.